Description

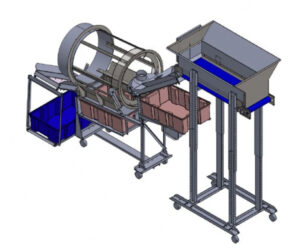

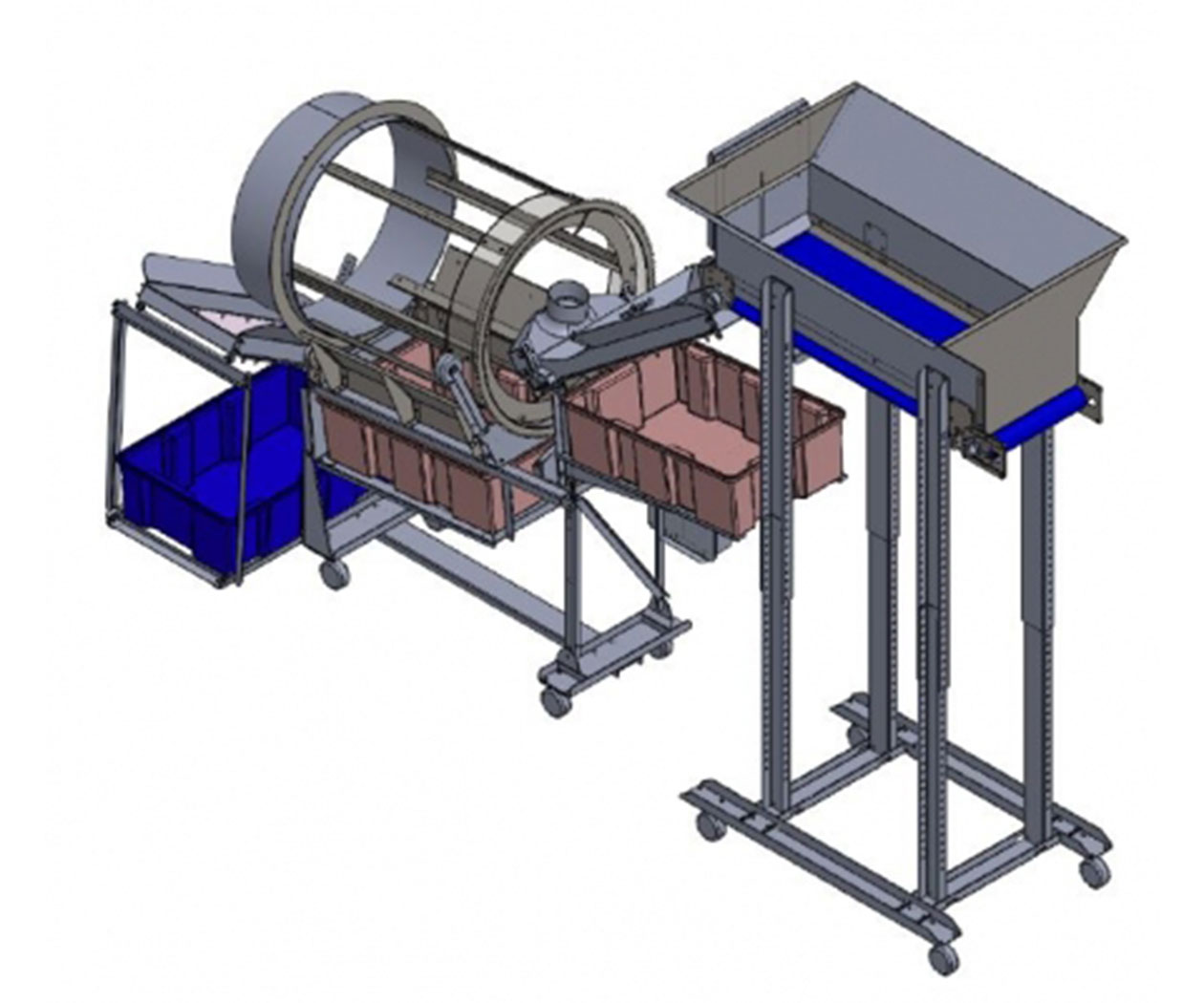

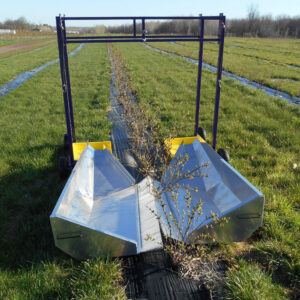

– 1 Standard De-leafer

– 2 Intake Conveyor Hoppers

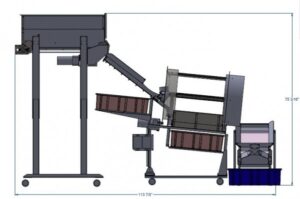

– 1 Sorting Conveyor Table

– 1 Drum Cleaner

Capacity will depend on number of workers, and how bad the berries to sort are. With a 1 person setup system, a single worker can get from raw berries to packaged berries in a 10 kg. box at a rate of 20-40 kg./hour. With 2 workers, the rate can be doubled and so on. Ideally a maximum of 3 workers at a time. There is 1 variable speed 1/4 hp gear motor per machine. The variable speed drive requires 220V 1PH.

The system must be operated in a room with a controlled temperature. Ideal temperature is -20 Celsius.

The minimum space required is 12’x14′.

Please contact for pricing

(1 Standard De-Leafer) – Leaves are taken care of before and after the destemmer. Smaller debris goes through the mesh of the destemmer.

(2 Intake Conveyers Side by Side) – Hopper can hold up to 65 kg. However, 30 kg. is best when used in slow-speed with door partially closed. The conveyer opening is 24″x36″ so works perfectly with our standard yellow trays which are 18″x24″ (Sold Separately).

(1 Sorting Conveyer Table)

(1 Drum Tumbler) – Standard 4 x 4 Mesh. It will remove debris and immature berries but will keep your ripe berries.

Reviews

There are no reviews yet.